Dana Industrial Carden Shafts

Series 587

Torque Range TCS - From 43 to 57,000 Nm

Flange diameter - From 225mm to 285mm

Series 587

Torque Range TCS - From 60 to 255,000 Nm

Flange diameter - From 285mm to 435mm

Key Features - Series 587

- Closed bearing eyes

- Compact design

- Low maintenance

- Splines coated with lubricating

varnish (587.50– plastic-coated)

- Operating angle up to 24°

Key Features - Series 390

- Maximum bearing life in confined

spaces

- Split bearing eyes with toothed

bearing cap

- Compact design

- Optimized roller bearing

- Length compensation coated with

lubricating varnish

- Operating angle up to 15°

Applications – Series 587

- Railway vehicles

- Rolling mill plants

- Marine drives

- General machinery construction plants

Applications – Series 390

- Railway vehicles

- Marine drives

- Crane systems

- Paper machines

- General machinery construction plants

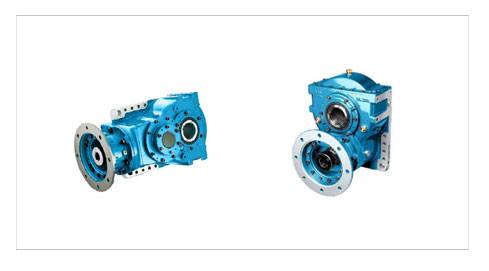

Applications

- Mining- Smaller

conveyors, crusher

- Bulk Material

Handling – Conveyor Drives,

Cranes, Overhead Gantry Cranes, Portable Conveyors etc.

- Steel – Roller

Drives

- Cement – Crushers,

Conveyors, Elevators,

Packaging

- Food & Beverages –

Packaging, Conveyors

- Pharma – Agitators,

Conveyors

- And variety of other

segment